Let’s find the right IR or UV system for your production line.

Traditional wood finishing slows you down

- Natural and hot air drying = slow, inconsistent, energy-hungry

- Bottlenecks in production lines

- Quality defects from uneven curing

Manufacturers need fast, precise, energy-efficient curing to meet demand without compromising finish quality.

Imagine curing coatings in seconds: with flawless finishes, less energy and zero production bottlenecks. Victory’s UV and IR technologies are powering the next generation of wood manufacturing lines across the UK, Europe and North America.

Victory systems cure coatings faster, cleaner and more consistently

Infrared (IR):

- Rapid drying with uniform heat distribution

- Dramatic time savings over hot air

- Ideal for adhesives, primers, and bulk drying

Ultraviolet (UV):

- Precise curing of coatings & lacquers

- Perfect, durable finishes every time

- Works with Gallium lamps or UV LED systems

Use IR and UV together for complete wood finishing lines — from base coat to final gloss.

- 35% line speed increase at UK kitchen manufacturer

- Installed systems in over 20 countries

- OEM partnerships with leading finishing equipment suppliers

Featured Wood Processing Systems:

Medium Pressure Gallium UV Lamps

High-intensity curing for superior lacquer finishes

- Specifically for kitchens, furniture & doors

- Consistent output, long life

- UK-manufactured precision

UV LED Curing Systems

Energy-efficient, cold curing technology

- Air-cooled or cold UV options

- Perfect for heat-sensitive finishes

- Modular, easy to retrofit

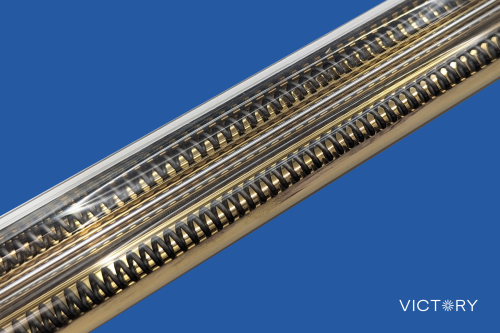

Infrared Twin Tubes

Precision heat for perfect curing

- IR lamps engineered for wood processing

- Fast response, energy-efficient

- Ideal paired with UV for full lines

Wood Processing Applications & Industry Use

Victory’s IR & UV technologies are trusted across a wide range of wood manufacturing processes, including:

Lacquer curing for kitchens, furniture, decorative panels

High-speed production lines & special finishes requiring precise control

OEM integration for new equipment

Retrofits to boost throughput and quality

Why Wood Manufacturers Choose Victory

- British-made UV & IR systems — fast lead times, precision build

- Custom-engineered solutions for wood manufacturing

- Direct engineer support — no call centres

- Serving UK, Europe & North America

- 30+ years’ industrial heating & lighting experience

Why Upgrade to Victory IR & UV Systems

- 3× faster than hot air drying

- 40% energy savings with UV LED

- Longer lifetime, lower maintenance

- Consistent curing, flawless finishes

Download Our Wood Processing Solutions Brochure

Get a detailed overview of our full product range, specifications and applications for wood manufacturing.

Get in touch for Wood Processing Solutions

Victory provides advanced Infrared (IR) and Ultraviolet (UV) systems designed specifically for wood processing.

- Infrared (IR): Uniform heat distribution, rapid drying, dramatic time savings over hot air and natural methods.

- Ultraviolet (UV): Precise curing of coatings and adhesives, delivering durable, high-quality finishes.

The right solution depends on your coating type and finish requirements — and we can guide you to the best choice for your production line.

Wood Processing: Technical Resources & Articles

5 Mistakes Wood Manufacturers Make with Coating Curing (And How to Avoid Them)

Avoid common wood coating curing mistakes and boost production efficiency with Victory Lighting’s IR and UV solutions. Learn how to prevent issues like uneven finishes, slow drying, and high energy use, while achieving flawless, durable wood coatings.

The Complete Guide to UV Curing in the Wood Coating Sector (2025 Edition)

UV curing is transforming the wood coating sector, giving manufacturers faster production speeds, consistent high-quality finishes and improved energy efficiency. From furniture and flooring to industrial manufacturing, this guide shows how UV and UV LED technologies are helping modern finishing lines meet rising performance and sustainability demands.

Victory at LIGNA 2025: Real Conversations, Smart Tech and a Bright Future for Wood Processing

Our Sales Director, Toby, spent two packed days on the ground; chatting with manufacturers, engineers and innovators about where the sector’s heading and how technologies like infrared and ultraviolet are quietly transforming the way things get done.