Let’s find the right IR or UV system for your production line.

Proven infrared and ultraviolet technology for automotive production, finishing and repair. Designed around your process, not off-the-shelf assumptions.

- IR & UV for OEMs, manufacturers & bodyshops

- Bespoke systems built in the UK

- Trusted across the UK & Europe

A Different Approach to Automotive IR & UV Technology

Victory has supported the automotive industry for years with reliable infrared solutions for manufacturing, finishing and repair. Today, we’re expanding that expertise across IR and UV technologies, supporting both established and fast-growing automotive applications.

Where others sell standard products, we design solutions around real-world automotive processes.

From battery manufacturing and windscreen production to paint curing and wheel repairs, our IR and UV systems integrate seamlessly into your operation to improve performance without disrupting workflows.

Why Automotive Manufacturers Choose Victory

- Solutions designed around real-world automotive processes

- Proven performance in demanding production environments

- Flexible, agile manufacturing and R&D support

- Competitive pricing without compromising quality

- A partner mindset — from concept through to installation and beyond

Automotive-Ready IR & UV Products:

Paint Dryers (IR & UV)

Efficient, controlled curing for automotive coatings, reducing cycle times and improving finish quality.

UV LED Paint Dryer

Energy-efficient UV curing with consistent output and fast response times.

VLP40 UV – New Version

Enhanced performance UV solution for demanding automotive processes.

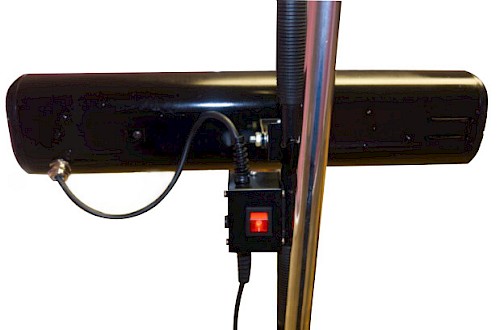

Contour IR Lamps

Designed for complex shapes such as headlights and plastic components.

Automotive Applications We Support

Our infrared and ultraviolet technologies are used across a wide range of automotive manufacturing, finishing and repair processes.

Manufacturing & Production

Our IR and UV systems support automotive manufacturing processes such as battery production, windscreen manufacturing, curing inks on automotive glass, and forming plastic and headlight components, helping manufacturers maintain quality while improving throughput and process control.

Paint Curing & Finishing

Victory provides infrared and UV solutions for automotive paint curing, including IR in spray booths, UV LED paint curing and fast bake ovens, enabling faster cycle times, consistent finishes and reduced energy consumption across production and finishing lines.

Bodyshop & Repair Applications

For bodyshops and repair centres, our IR and UV technology supports paint repairs, alloy wheel refurbishment and localised curing, with handheld IR dryers and compact systems designed for flexibility, speed and ease of use. They reduce downtime, improve quality and support consistent results.

Specialist & Bespoke Automotive Processes

We work closely with customers on bespoke IR and UV solutions for specialist automotive applications, designing systems to integrate seamlessly into new or existing production lines where standard equipment isn’t fit for purpose.

Built for Your Process — Not Off the Shelf

No two automotive production lines are the same. That’s why Victory specialises in bespoke IR and UV solutions.

Whether you’re integrating infrared into a new battery production line, improving curing consistency in a spray booth, or developing a solution for complex glass or plastic components, our engineers work closely with you to deliver the right outcome.

What you get:

- Application-led system design

- Custom lamp configurations and layouts

- Integration support for new or existing lines

- Scalable solutions to support production growth

Why Use Infrared & UV Technology in Automotive Manufacturing?

- Faster curing and reduced cycle times

- Improved quality control and consistency

- Energy-efficient heating and curing

- Precise, targeted application

- Reduced waste and rework

Infrared and ultraviolet technologies are becoming essential in modern automotive manufacturing, and Victory helps you deploy them with confidence.

Speak to an Automotive Specialist

Download Our IR & UV for Automotive Brochure

Get a detailed overview of our full product range, specifications and applications for automotive manufacturing.

Automotive IR & UV – Frequently Asked Questions

What are infrared and UV systems used for in automotive manufacturing?

Infrared and UV systems are used for paint curing, coating drying, heating, forming plastics, curing inks on glass, and supporting battery manufacturing processes.

Can Victory provide bespoke IR or UV solutions for automotive OEMs?

Yes. Victory specialises in application-led, bespoke IR and UV solutions designed around your specific production requirements.

Are IR and UV curing systems energy efficient?

Yes. Modern IR and UV LED systems offer fast response times, targeted energy use and lower overall energy consumption.

Do you support both production lines and repair environments?

Absolutely. Our solutions are used in high-volume manufacturing, bodyshops, wheel repair centres and aftermarket environments.

Do you supply outside the UK?

Yes. Victory supports automotive customers across the UK, Europe & North America.